Inventory Management Fundamentals Explained

Wiki Article

Facts About Inventory Management Revealed

Table of ContentsInventory Management Things To Know Before You Get ThisThe Best Strategy To Use For Inventory ManagementA Biased View of Inventory ManagementInventory Management - TruthsInventory Management Fundamentals Explained

The routine inventory system is a method of supply evaluation for economic reporting purposes in which a physical matter of the inventory is done at details periods. This accounting method takes inventory at the start of a period, adds brand-new stock purchases throughout the duration and also deducts ending supply to obtain the price of items offered (GEARS).They can link several information points to the number, including the supplier, product measurements, weight, as well as also variable information, such as the number of are in supply. RFID or radio regularity recognition is a system that wirelessly sends the identity of a product in the type of an unique identification number to track items and supply thorough item details.

The Buzz on Inventory Management

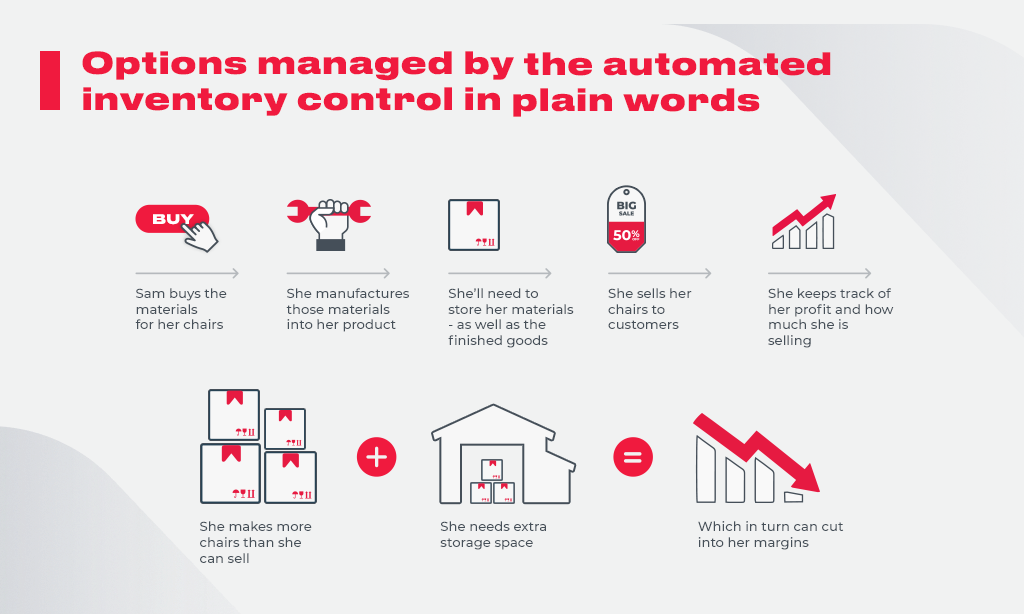

Inventory management describes the procedure of saving, buying, as well as selling of items as well as services. The self-control additionally includes the monitoring of different materials and processes. One of the most vital elements of supply administration is managing the flow of raw products from their purchase to finished items. The objective is to decrease overstocks as well as boost effectiveness so that tasks can remain on time and within spending plan.An oil depot can save a massive stock for a long time. Or for organizations that handle disposable items, such as fast-fashion items, continuing top of your stock can be extremely costly. One means to account for stock is by organizing it right into four groups: first-in-first-out, last-in-first-out, weighted-average, and first-in-first-out.

Depending on the type of company that it is dealing with, different supply management techniques are utilized. Some of these include JIT, product demand preparation, as well as days sales of inventory.

The Buzz on Inventory Management

Discover also much more concerning stock management from Walton College's Supply Chain Monitoring program's introduction on the subject covering whatever from projecting to direct designs: Among one of the most beneficial properties of a business is its supply. Inventory Management. In different sectors, such as retail, food services, and manufacturing, an absence of supply can have harmful results.It can be prone to theft, damage, and wasting. Having a huge supply can likewise lead to a decrease in sales. Both for tiny businesses and also big companies, having an appropriate supply administration system is very important for any kind of service. It can assist you keep an eye on all your products and also figure out the exact rates.

This is particularly crucial for brands seeking to come to be a more customer-centric company. Balancing the threats of overstocks and lacks is an especially tough process for companies with redirected here intricate supply chains. A firm's inventory is generally an existing property that it prepares to market within a year. Inventory Management. It has to be gauged as well as counted consistently to be thought about an existing asset.

Some Known Incorrect Statements About Inventory Management

This suggests enabling them complete openness into their chain to monitor the flow of products from their distributor. The advantages are both functional and also financial. Not only will it serve to boost efficiency, yet it's likewise helpful for avoiding burglary with the help of item monitoring and safety. Managers can also aim to use their supply monitoring strategy to keep an eye on sales treatments which results in better solution.

Offering consumers numerous different kinds of internationally-grown fruit and vegetables in both organic and non-organic selections at an affordable price, also when the vegetables and fruits aren't in period, is a contemporary wonder thanks partly to inventory monitoring. Supervising supply in actual time as well as even setting up automated replenishment systems is mission-critical to lots of.

Indicators on Inventory Management You Should Know

6 million plans from their brand name to third-party vendors daily. Their Smart Stockroom utilizes robotic and human assistance to do the job, however it's stock monitoring that maintains everything pop over to this web-site rolling. According to Technology Vision, "Amazon.com's management technique, along with all that automation, have made business tremendously lean as well as indicate by historical criteria." The stock monitoring of toilet tissue companies remained in the spot in early 2020 as panic-buying caused scarcities nationwide.

Below are the primary kinds you need to understand: Basic material, This describes items of your item that requirement to be shipped to you as well as set up by your team. Stock systems that track these need to represent supplier timelines. Underway, Products made from basic materials and also are currently being assembled or organized loss under this category.

Report this wiki page